Introduction

When growing organic vegetables, weeding represents one of the most important and frequent activities to control both the quality of the field and its produce. In recent years, automated intra-row weeding machines have entered the market, greatly facilitating the weeding process. The most advanced weeding machines use machine vision applications to distinguish crops from weeds. As the camera systems’ sensor data is a valuable information source, this use case collects location-specific camera data to provide insights on the number of vegetables growing on the field, the plants’ growth status and best harvesting moment, weed prevalence, nutrient shortages and drought stress.

Incremental improvement and development phases

When growing organic vegetables on the field, one of the main tasks is weeding. The weeding represents a major part of the labour required on the field, but it is of great importance for the quality of the crop.

Show more

The intra-row weeding machines of this use case are based on vision systems which detect the weeds in the crop. In these advanced machines there are several cameras which acquire images of the crop and weeds. After the weed is detected in the images, the only action done is hoeing the weed. Until now there is no further processing of the images to gather valuable information. Hence, Jos Ruizendaal, the Use Case Coordinator, and his team aim to harness the entire benefits of the images collected in the field.

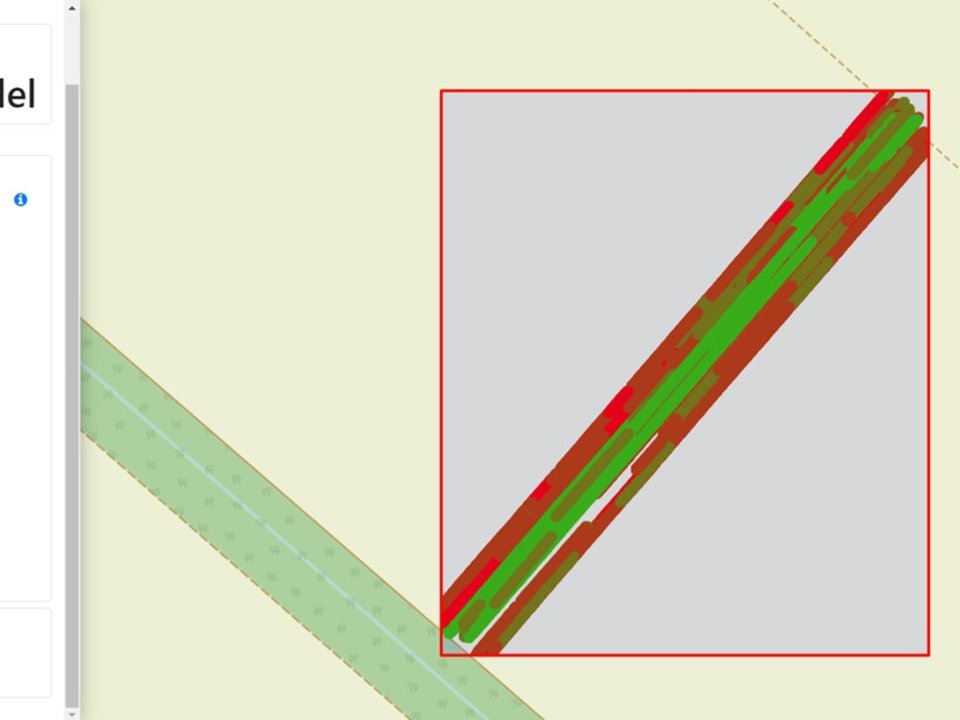

After the initial project phase, the use case decided to implement new cameras with a higher resolution in one of the weeders for image recording. The original cameras in the weeding machine gave sufficient information to detect the weeds but defining crop parameters was not accurate enough. To achieve the objective of improving the crop model, a higher resolution image gives better data from the field and therewith a better starting point for image analysis. The cameras were successfully implemented and the complete machine was evaluated to make sure the higher data volume would not influence the weeding performance. The gathered high-resolution images of the crops and weeds did not only enhance the weeding performance, but also enabled better results on crop and yield prediction. Furthermore, the researchers derived insights on crop growth, weed pressure and harvest moment from the images. After processing, the data is presented as heat maps to the grower, which can be viewed in all main farm management systems. By structuring the data in a user-friendly way, the grower gets the necessary support to make better informed choices and thereby grow crops more efficiently. For data visualisation an application on akkerweb.nl, an online platform, was developed. During the project this company has evolved to farmmaps.eu to extend the services to international customers. The appearance and basic functionality of akkerweb.nl, however, has remained the same. The improvement of the application concerning user friendliness was necessary because when larger field sizes were logged and uploaded to akkerweb the performance of visualisation of the yield maps was poor. Therefore, changes in the way the data was processed on the akkerweb platform were made by the researchers alongside improvements on the graphical interface of the platform. As a result, when a field is now opened on farmmaps, it starts with an overview of the field with average values of the crop parameters. The end-user can derive insights on performance differences in the field by zooming in to individual data points. This enables monitoring individual crops as each data point contains a plethora of information such as crop size and diameter of a crop. The latter has been validated to improve the yield prediction by the crop growth model. As the weeding operation is based on the detection of crops in the field an accurate diameter calculation of the crops is important. In addition to that, improving the accuracy of the calculated diameter allows the machine to improve the weeding operation as well.

-5%

Machine running hours

+5%

Yield

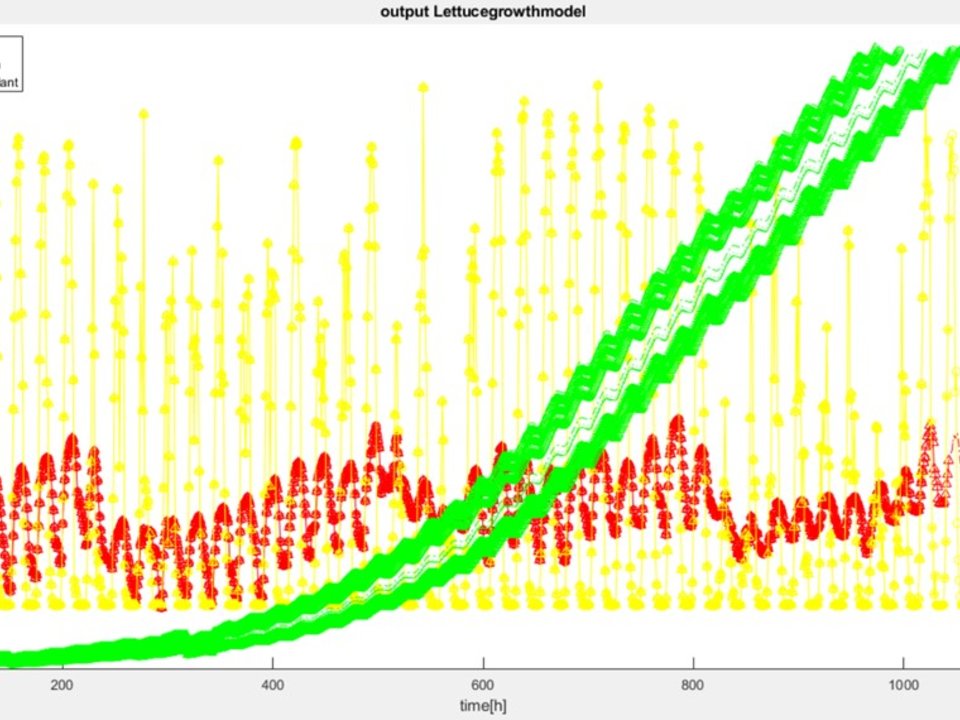

Crop growth of butterhead and iceberg lettuce, which are the main crops this use case works with, have been validated based on extensive field trials. To refine the results the use case team compared the calculated crop parameters from the high-resolution cameras to manual measurements. This way the researchers could be certain that their calculated crop parameters have a high accuracy and thereby enable the precise yield prediction with the crop growth model. One aspect that improved with every season was the accuracy of the predicted harvest date calculated with the lettuce growth model. Furthermore, the visualization of the heatmaps on farmmaps has been improved as well. The results are shown per 100 plants average, clearly indicating which fields should be harvested first. Since the differences are shown within each field it even gives farmers the opportunity to perform selective harvesting in one field. To calculate the predicted harvest date a user-friendly graphical user interface (GUI) has been build that allows the end-users to access the insights through simple icons. It does not only enable the farmers to calculate the most optimum harvest date, but to harvest crops with the desired size.

Challenges and lessons learned

Even though the implementation of higher resolution cameras improved the results of the crop parameters calculation, the higher data volume caused stability issues with the software on the weeding machine.

Show more

The issues were caused by the implementation of higher resolution cameras resulting in a higher data volume. It was foreseen that the higher data load needs more computing power. Hence, during the winter the use case team used the time for tests and adaptations to the software to handle the increased data load. Nevertheless, some issues arose during the first field measurements. Fortunately, the issues were solved quickly at the start of the season by implementing a software update on the machine itself. As the machine is equipped with connectivity the update could even be done remotely by the team. This shows the importance of actual field tests which improve the testing procedure. As there were no suitable crops available during winter this was, however, not possible. The increased data volume of the images also created another issue with the data logging. This decreased the maximum driving speed of the tractor pulling the intra-row weeding machine at the start of the season. By implementing a faster logging procedure, the researchers resolved this challenge as well, thereby enabling normal driving speed during the weeding operation.

-60%

Yield prediction errors

+5%

Labour efficiency

The lettuce crop was grown in different growth cycles during the year to ensure different climate conditions for the crop. During one of the growth cycles the crop was lost shorty after planting. Although the plants were watered sufficiently, they suffered severe drought during the summer heat wave. Therefore, the team had to replant the crop shortly after the heat wave. But that is not all, nature confronted the use case with another challenge: due to a bug plague (Rüben Rüsselkäfer) the sugar beets at the organic farmer were lost shortly after the crops emerged from the soil. The fields were replanted but this resulted in another invasion of the bugs and the crop was lost again. As there was no way to control the bug plague and spraying the fields was not allowed due to the organic nature of the farm, the crop was completely lost in two years of the project. Therewith also the chance for the researchers to further validate their solution applied to sugar beets.

In one test field of Wageningen University & Research the team simply captured the images without carrying out the weeding operation. This enabled them to capture data of fields with high weed pressure in the field. In emerging stages of weeds the crops and weeds could be segmented very well. As there was no weed management in these specific fields the weeds grew along with the crop and at a certain moment the weeds and crop started to cover the complete soil. In images with only limited or no bare soil visible it is not possible anymore to segment crops from weeds to calculate crop surface. As farmers normally start early with the weed control this is not common practice but if weeding in fields with very high weed pressure is required another segmentation approach of the weeds is needed.

One lesson the use case team learned was that the accuracy of planting plays and important role. In some fields this was not done precisely, causing deviations in crop distance, a left/right offset and intra row distance in a bed. These deviations in planting distance had more influence on the crop detection than the researchers expected. Since the machine detects the crops and the regularity in crops is used in the software, the soil preparation and planting both have a significant influence on crop calculation and thus weeding performance. When the deviations are too big, it decreases the machine performance. A challenge that the use case team is currently tackling to better cope with high irregularity in planting in the future.

Sustainability in the future

Connectivity in rural areas can oftentimes be poor or not existent at all, making it impossible to upload data from the field to the cloud. To solve this, the data is stored locally on the machine and uploaded once the farmer returns from the field and enters a connectivity point.

Show more

The challenges of deploying broadband in rural and remote areas not only include the more obvious ones - lower population densities, longer distances and rougher terrain - but also the less obvious challenges that can do more for the success or failure of a project. Once the connectivity challenge is addressed sufficiently, European farmers will be able to fully leverage the potential of precision farming. In terms of precision agriculture, monitoring crops and predicting yields will be more and more important in the coming future. Due to more and more restrictions on herbicides, mechanical weed control will be increasingly important as well. Since the use case team combined both aspects in their research, their Steketee IC-Weeder equipped with a plant monitoring software is built for the future.

Get in touch with the use case team via the SmartAgriHubs Innovation Portal

Go to portalAchievements, products & services

Based on the insights, the farmers or crop advisors to improve the management of the crops

Crop parameters are sent to an online database, supplemented with yield and field data, and presented in a user-friendly way

Steketee IC-weeder taking and processing images of the crop on board

Reduction of field labour while increasing yield